The force transmitted through a rope or cable supporting a weight when redirected by a wheel or axle is a fundamental concept in mechanics. For example, lifting a heavy object with a simple system involving a rope looped over a stationary wheel demonstrates this principle. The force required to lift the object is distributed along the rope, enabling mechanical advantage.

Understanding this force distribution is crucial for designing and analyzing various mechanical systems, from elevators and cranes to more complex machinery. Its application has simplified lifting and moving heavy loads for centuries, facilitating the development of infrastructure and technology. This principle laid the foundation for many modern engineering marvels and continues to be relevant in contemporary mechanics.

This exploration will delve deeper into the calculation of this force, factors influencing it, different pulley systems, and practical applications in various engineering disciplines.

Tips for Working with Mechanical Advantage Systems

Optimizing mechanical systems requires careful consideration of the forces involved. The following tips offer guidance for effectively utilizing such systems.

Tip 1: Account for Friction: Ideal calculations often neglect friction. In real-world applications, friction between the rope and the pulley, and within the pulley’s axle, reduces the actual mechanical advantage achieved. Lubrication and appropriate material selection can minimize these losses.

Tip 2: Rope Material Matters: The rope’s tensile strength is crucial. Selecting a rope with insufficient strength can lead to failure. Consider the load and choose a rope with an appropriate safety factor.

Tip 3: Pulley Material and Design: Pulley material and bearing design influence efficiency. High-quality bearings minimize friction, improving system performance. Pulley material should be strong and resistant to wear and deformation.

Tip 4: System Complexity: While complex pulley systems offer greater mechanical advantage, they also introduce more points of potential failure. Consider the trade-off between mechanical advantage and system complexity when designing a lifting mechanism.

Tip 5: Angle of Application: The angle at which the force is applied to the rope can affect the tension within the system. Sharp angles can increase stress on the rope and pulley, reducing efficiency.

Tip 6: Environmental Factors: External factors such as temperature and humidity can impact rope strength and pulley performance. Consider these environmental conditions when selecting materials and designing systems.

By understanding these factors, engineers and operators can design, operate, and maintain safer and more efficient lifting mechanisms, reducing wear and tear while maximizing performance.

These considerations contribute to a comprehensive understanding of force transmission in mechanical systems, enabling informed design choices and safe operation.

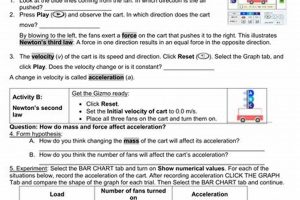

1. Force Multiplication

Force multiplication is a core principle in pulley systems. It explains how a smaller applied force can lift a much heavier load. This multiplication is achieved by distributing the required lifting force over a longer length of rope. The rope, redirected by multiple pulleys, effectively increases the distance over which the input force acts. Consequently, while the work done remains constant (force x distance), the input force is reduced proportionally to the increased distance the rope travels. A classic example is a two-pulley system where lifting a weight a certain distance requires pulling the rope twice that distance, effectively halving the required input force. This principle is crucial for practical applications such as lifting construction materials or operating heavy machinery where direct lifting would be impractical or impossible.

The tension in the rope plays a critical role in force multiplication. Each segment of the rope supporting the load contributes to the total lifting force. In a multi-pulley system, the load is shared among multiple rope segments, and the tension in each segment is a fraction of the total load. This distribution of tension is what allows a smaller input force to balance and overcome the weight of a larger object. Analyzing tension distribution is crucial for understanding how the mechanical advantage is achieved and ensuring the system’s structural integrity. For example, in a four-pulley system, the tension in each rope segment is approximately one-fourth the weight of the load, assuming ideal conditions (negligible friction and rope weight). This reduction in tension per segment allows for the use of lighter ropes and smaller pulleys, improving efficiency and practicality.

Understanding force multiplication is fundamental for designing and optimizing pulley systems. Calculating the mechanical advantage, which quantifies the force multiplication factor, allows engineers to select appropriate rope strengths, pulley sizes, and configurations for specific applications. While idealized calculations provide a theoretical basis, practical considerations like friction and rope elasticity must be factored into real-world designs. Overlooking these factors can lead to system inefficiency or even failure. A thorough understanding of the interplay between force multiplication and tension distribution, alongside practical considerations, is essential for designing reliable and effective lifting mechanisms.

2. Equilibrium Conditions

Equilibrium in pulley systems is achieved when the forces acting on the system are balanced. This implies a state of rest or constant velocity. Analyzing equilibrium is crucial for determining the tension distribution within the ropes and the force required to maintain the system’s state. Newton’s Second Law of Motion, stating that the net force acting on an object equals its mass times its acceleration, is fundamental to understanding equilibrium. In a static system (zero acceleration), the net force must be zero. This principle directly applies to pulley systems. For example, in a simple single-pulley system supporting a weight, the upward tension in the rope must equal the downward force of gravity acting on the weight. If these forces are unbalanced, the weight will either accelerate upwards or downwards.

In more complex pulley systems with multiple ropes and pulleys, the equilibrium condition applies to each individual pulley and the overall system. The tension in each rope segment contributes to balancing the load and any applied forces. Consider a two-pulley system lifting a weight. The tension in the rope attached to the ceiling must balance the combined weight of the load and the tension in the second rope segment. This distribution of forces ensures the system remains static. Ignoring equilibrium conditions can lead to system failure. If the applied force is insufficient to balance the load, the load will descend. Conversely, an excessive force can cause the load to accelerate upwards, potentially exceeding the rope’s tensile strength or damaging the pulley system. Practical applications, like construction cranes, rely heavily on precise equilibrium calculations to ensure safe operation.

Understanding equilibrium conditions is paramount for designing and operating safe and effective pulley systems. It allows engineers to predict the forces acting within the system and ensure that all components are appropriately sized and configured. This understanding, combined with an analysis of tension distribution, provides a comprehensive framework for analyzing and optimizing mechanical advantage systems. Challenges in real-world applications often involve accounting for friction and the dynamic forces introduced by movement. Addressing these challenges requires advanced analysis that builds upon the fundamental principles of equilibrium.

3. Ideal Mechanical Advantage

Ideal mechanical advantage (IMA) represents the theoretical force amplification achieved by a pulley system in the absence of friction. It directly relates to the number of rope sections supporting the load. Each supporting rope segment effectively distributes the load’s weight, reducing the required input force proportionally. A system with two supporting ropes, for example, theoretically halves the required input force, yielding an IMA of 2. This relationship between IMA and the number of supporting ropes is a fundamental principle in pulley tension physics. Analyzing tension distribution within the system reveals that the total tension supporting the load is distributed equally among these supporting ropes. In an idealized system, the tension in each rope segment equals the input force, demonstrating how a smaller input force, multiplied by the number of supporting ropes (the IMA), balances the load. This principle’s practical significance is evident in applications like lifting heavy equipment with a block and tackle system, where multiple pulleys and rope segments create a significant mechanical advantage, enabling lifting with a manageable input force. However, realizing the full theoretical IMA is practically impossible due to real-world factors like friction.

While IMA provides a valuable theoretical benchmark, actual mechanical advantage (AMA) always falls short due to friction and other losses. Friction within the pulley bearings and between the rope and pulley dissipates some of the input force as heat, reducing the system’s efficiency. This difference between IMA and AMA underscores the importance of considering real-world factors when designing pulley systems. For example, selecting low-friction pulleys and appropriate rope materials can minimize losses and improve efficiency. Moreover, rope elasticity and weight, often neglected in idealized calculations, contribute to a further reduction in AMA. In high-load applications like crane systems, understanding and mitigating these losses are critical for safe and efficient operation. Calculating the efficiency of a pulley system, which is the ratio of AMA to IMA, provides a valuable metric for assessing system performance and identifying areas for improvement.

The relationship between IMA and tension distribution provides fundamental insight into how pulley systems achieve force multiplication. While IMA offers a theoretical maximum, practical design must account for real-world factors that influence tension distribution and reduce efficiency. Understanding these factors, coupled with careful material selection and system design, allows engineers to optimize pulley systems for specific applications, maximizing their performance and ensuring safe operation. Further exploration of pulley tension physics involves analyzing more complex pulley configurations, considering dynamic loads, and addressing the limitations of idealized models in real-world scenarios.

4. Friction and Efficiency

Friction plays a critical role in the efficiency of pulley systems. Idealized models often neglect friction, assuming perfect energy transfer. However, in real-world applications, friction inevitably arises at various points, primarily between the rope and the pulley wheel, and within the pulley’s axle bearings. This friction converts some of the input work into heat, effectively reducing the system’s output work and therefore, its efficiency. The force required to overcome this friction adds to the input force, diminishing the actual mechanical advantage compared to the ideal mechanical advantage. For instance, a pulley system designed to lift a 100N load might theoretically require only 50N of input force with an ideal mechanical advantage of 2. However, frictional losses could increase the required input force to 60N, reducing the actual mechanical advantage to approximately 1.67. This reduction in efficiency is a crucial consideration in applications like lifting heavy construction materials or operating elevator systems where energy losses directly translate to increased power requirements and operating costs.

The impact of friction on efficiency becomes increasingly significant in complex pulley systems with multiple pulleys and rope segments. Each point of contact between the rope and a pulley, and each rotating axle bearing, contributes to frictional losses. Consequently, systems with higher ideal mechanical advantages, achieved through multiple pulleys, can experience more substantial efficiency reductions due to the cumulative effect of friction at multiple locations. Lubrication and the use of low-friction bearings can mitigate these losses. Selecting appropriate rope materials also plays a crucial role. Ropes with rough surfaces generate greater friction against the pulley wheel, further reducing efficiency. Understanding these factors enables engineers to optimize pulley system design by selecting components and materials that minimize frictional losses and maximize energy transfer. Furthermore, regular maintenance, including lubrication and component replacement, is crucial for maintaining system efficiency over time. In critical applications, implementing monitoring systems to detect early signs of wear and increased friction can prevent costly downtime and potential safety hazards.

The relationship between friction and efficiency in pulley systems is a key aspect of practical mechanical design. While idealized models provide a theoretical framework, incorporating frictional losses into calculations ensures realistic performance predictions. Addressing these losses through appropriate material selection, lubrication, and system design is crucial for optimizing efficiency and minimizing energy consumption in various real-world applications. Accurately assessing efficiency enables informed decisions about power requirements, operating costs, and component lifespan. Further analysis may involve quantifying frictional losses, evaluating different lubrication strategies, and exploring the trade-offs between mechanical advantage, system complexity, and efficiency in specialized pulley applications.

5. Tension Distribution

Tension distribution is fundamental to understanding how pulley systems function and achieve mechanical advantage. Analyzing how tension forces are distributed throughout the ropes and around the pulleys provides crucial insights into system equilibrium, force multiplication, and overall efficiency. This exploration delves into the key facets of tension distribution within pulley systems.

- Uniform Tension in Ideal Systems

In idealized pulley systems, neglecting friction and rope weight, tension remains uniform throughout the rope. This uniformity implies that each segment of the rope experiences the same tensile force. This principle simplifies calculations and allows for straightforward determination of mechanical advantage based on the number of supporting rope segments. For example, in a two-pulley system lifting a weight, the tension in each segment of the rope equals half the weight, facilitating force multiplication.

- Impact of Friction on Tension Distribution

Friction disrupts the uniform tension distribution. Friction between the rope and the pulley, as well as within the pulley bearings, introduces additional forces that alter the tension along the rope. The tension tends to be higher in the rope segment pulling away from the driving force and lower in the segments supporting the load. This uneven distribution affects the actual mechanical advantage, reducing it compared to the ideal theoretical value. Consider a crane lifting a heavy load; the rope segment directly connected to the motor experiences higher tension due to the combined load and friction within the system.

- Tension in Multiple Pulley Systems

In more complex pulley systems involving multiple pulleys and rope segments, analyzing tension distribution becomes more intricate. The tension in each segment depends on its position within the system and the configuration of the pulleys. In a block and tackle system, the tension in each rope segment supporting the load is a fraction of the total weight, distributing the load among multiple segments and enabling substantial force multiplication. This principle is crucial for lifting extremely heavy objects with a relatively small input force. Analyzing the forces acting on each pulley and rope segment provides insight into the overall tension distribution and equilibrium conditions.

- Relationship between Tension and Mechanical Advantage

Tension distribution directly relates to the mechanical advantage of a pulley system. The number of rope segments supporting the load, and the tension within each segment, determines the overall force multiplication factor. Higher mechanical advantages involve more rope segments, each carrying a smaller fraction of the total load. This distribution of force through multiple rope segments enables lifting heavier objects with a smaller applied force. However, increasing the mechanical advantage by adding more pulleys also increases the system’s complexity and the potential impact of friction on efficiency. This interplay between mechanical advantage, tension distribution, and friction underscores the importance of careful design considerations in practical applications.

Understanding tension distribution is crucial for analyzing and designing effective pulley systems. From the idealized uniform tension in frictionless scenarios to the complex distribution in multi-pulley systems, analyzing tension provides essential insights into how these systems achieve mechanical advantage, manage loads, and balance forces. Considering friction’s impact on tension distribution bridges the gap between theoretical models and real-world performance, enabling the design of practical, efficient, and safe lifting mechanisms.

6. System Complexity

System complexity in pulley systems directly influences tension distribution and overall mechanical advantage. Simpler systems, like a single fixed pulley, exhibit straightforward tension relationships where the tension in the rope equals the applied force or load weight. However, as systems incorporate multiple pulleys, both fixed and movable, the tension distribution becomes more intricate. In compound pulley systems, each rope segment experiences varying tension depending on its position and function within the system. A greater number of pulleys and rope segments generally leads to a higher mechanical advantage, distributing the load across more ropes and reducing the force required to lift the load. This increased complexity, however, presents challenges in analyzing tension distribution. For instance, in a block and tackle system used for hoisting heavy equipment, the tension in each rope segment contributing to the lift is a fraction of the total load, requiring careful analysis to ensure each segment’s strength is adequate. An error in calculating tension distribution in a complex system can lead to rope failure or improper load balancing, emphasizing the importance of understanding system complexity’s influence on tension.

Analyzing complex pulley systems necessitates considering factors beyond simple tension calculations. Friction within pulley bearings and between ropes and pulleys becomes more significant as the number of components increases, reducing the actual mechanical advantage achieved. Predicting system behavior under load becomes more challenging with greater complexity, requiring advanced analytical techniques. For instance, designing a crane system with multiple pulleys involves calculating not only the tension distribution but also the forces acting on each pulley’s support structure, ensuring the entire system’s stability. Furthermore, the elasticity and weight of the rope itself become more relevant in complex systems with longer rope lengths. These factors can influence tension distribution and overall system dynamics, demanding more sophisticated models for accurate analysis. Ignoring the added complexity in such systems can lead to inaccurate predictions of system behavior, potentially compromising safety and efficiency.

Understanding the relationship between system complexity and tension distribution is crucial for designing and operating effective pulley systems. While simpler systems offer easier analysis, more complex configurations provide greater mechanical advantage, enabling the lifting of heavier loads with smaller applied forces. However, this increased complexity demands more rigorous analysis, accounting for friction, rope properties, and the forces acting on all components. Practical applications, ranging from simple lifting devices to complex crane systems, require a thorough understanding of this relationship to ensure safety, efficiency, and predictable performance. Overlooking the implications of system complexity can lead to design flaws, operational inefficiencies, and potential safety hazards, underscoring the importance of comprehensive analysis in pulley system design and operation.

7. Real-world applications

Pulley tension physics finds extensive application in a wide array of practical scenarios, demonstrating its relevance beyond theoretical models. Understanding tension distribution, mechanical advantage, and the influence of friction is crucial for designing, operating, and optimizing these real-world systems. The following examples highlight the diverse applications of these principles.

- Lifting and Hoisting Systems

Cranes, elevators, and winches rely heavily on pulley systems to lift and lower heavy loads. Analyzing tension distribution is crucial for ensuring the ropes and supporting structures can withstand the forces involved. The mechanical advantage achieved through multiple pulleys enables lifting massive objects with manageable input forces. In construction, cranes utilize complex pulley systems to move building materials, while elevators employ similar principles for vertical transportation. The safety and efficiency of these systems depend critically on the proper application of pulley tension physics.

- Exercise Equipment

Many exercise machines, such as cable weight systems and resistance training apparatus, utilize pulleys to create adjustable resistance forces. The tension in the cables provides the force against which muscles work. Understanding pulley mechanics allows for precise control of resistance levels, facilitating targeted strength training. Different pulley configurations provide varying mechanical advantages, influencing the force required for each exercise. This application demonstrates pulley principles in a context directly related to human biomechanics and physical performance.

- Automotive Systems

Pulley systems play a role in various automotive applications, including power steering and engine timing belts. Power steering systems use pulleys and belts to transmit force from the steering wheel to the steering mechanism, reducing the effort required to turn the wheels. Timing belts, driven by pulleys, synchronize the movement of engine components, ensuring proper combustion and engine operation. The precise tension in these belts is crucial for efficient power transmission and engine performance.

- Sailing and Nautical Applications

Sailboats utilize pulley systems extensively for controlling sails and rigging. Sailors adjust sail positions using ropes and pulleys, allowing them to harness wind power effectively. The tension in the ropes controls the shape and angle of the sails, optimizing the boat’s performance in different wind conditions. Understanding tension distribution and mechanical advantage in this context is essential for efficient sailing and maneuvering.

These examples demonstrate the broad applicability of pulley tension physics. Analyzing tension distribution, understanding mechanical advantage, and accounting for friction are essential for designing and operating these systems effectively and safely. From lifting massive construction materials to precisely controlling resistance in exercise equipment, pulley systems and the underlying physics play a vital role in diverse real-world applications. Further exploration could involve examining specialized pulley systems in robotics, manufacturing, or theatrical stage rigging, further highlighting the widespread relevance of this fundamental area of physics.

Frequently Asked Questions

This section addresses common queries regarding the physics of pulley systems, aiming to clarify key concepts and dispel misconceptions.

Question 1: How does friction affect the mechanical advantage of a pulley system?

Friction reduces the actual mechanical advantage compared to the ideal theoretical value. It requires additional force to overcome frictional resistance within the pulley bearings and between the rope and pulley, diminishing the overall efficiency of the system.

Question 2: What is the difference between ideal mechanical advantage and actual mechanical advantage?

Ideal mechanical advantage (IMA) represents the theoretical force multiplication assuming no friction. Actual mechanical advantage (AMA) accounts for real-world factors like friction and represents the actual force multiplication observed in practice. AMA is always lower than IMA due to energy losses from friction.

Question 3: How is tension distributed in a complex pulley system?

Tension distribution in complex systems becomes more intricate. The tension in each rope segment depends on its position and function within the system, the configuration of pulleys, and the presence of friction. Analyzing each component’s force balance is essential to determine tension distribution.

Question 4: Why does increasing the number of pulleys increase the mechanical advantage?

Each additional pulley and supporting rope segment distributes the load further, reducing the force required on any single segment. This distribution of force multiplies the input force, leading to a higher mechanical advantage. However, adding more pulleys also increases friction, potentially reducing overall efficiency.

Question 5: How does the choice of rope material influence pulley system performance?

Rope material significantly impacts performance. A rope’s tensile strength determines its load-bearing capacity, while its surface properties influence friction. A rougher rope generates more friction against the pulley, reducing efficiency, while a smoother, stronger rope contributes to a more efficient system.

Question 6: What are the limitations of idealized pulley models?

Idealized models often neglect factors like friction, rope weight, and pulley mass, simplifying calculations but leading to discrepancies with real-world behavior. Considering these factors is crucial for accurate system design and performance prediction.

Understanding these fundamental principles is critical for designing, operating, and troubleshooting pulley systems effectively. Careful consideration of these factors ensures safe and efficient operation in diverse applications.

The next section delves further into advanced topics in pulley mechanics, including dynamic analysis and the influence of variable loads.

Conclusion

Analysis of forces within pulley systems reveals the intricate interplay between tension, mechanical advantage, and system complexity. Understanding tension distribution is fundamental for predicting system behavior and ensuring safe and efficient operation. From simple lifting mechanisms to complex machinery, the principles governing pulley tension physics remain crucial for optimizing performance and mitigating risks. Accounting for real-world factors like friction and material properties is essential for bridging the gap between theoretical models and practical applications. The ability to accurately calculate and predict tension within these systems is paramount for ensuring structural integrity and operational reliability.

Further exploration and refinement of analytical techniques in pulley tension physics will continue to drive advancements in engineering design and mechanical efficiency. As systems become more complex and demands increase, a deeper understanding of these principles remains essential for pushing the boundaries of mechanical innovation. The ongoing quest for optimized force transmission and enhanced load-bearing capacities necessitates continued research and development in this fundamental area of mechanics. A thorough grasp of these concepts empowers engineers to design robust, reliable, and efficient systems capable of handling increasingly demanding tasks, paving the way for future advancements in various technological domains.