Reducing a substance to smaller particles through mechanical force alters its form but not its composition. For example, coffee beans become ground coffee, but the chemical makeup remains the same. This contrasts with chemical changes where new substances are formed, such as burning wood which produces ash and gases.

Understanding the distinction between physical and chemical transformations is fundamental to various disciplines, from material science and cooking to geology and pharmaceuticals. This knowledge allows for predicting and controlling outcomes in processes involving material alteration. Historically, understanding these differences was crucial for advancements like developing metallurgy and medicine.

This principle underlies numerous everyday activities and industrial applications. Further exploration will cover specific examples of size reduction and their impact in different fields, including its role in increasing surface area for chemical reactions and enhancing material properties.

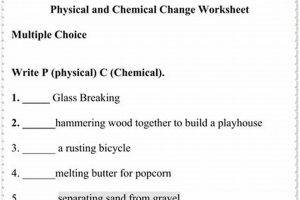

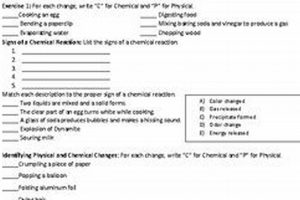

Tips for Understanding Physical Changes

Distinguishing physical from chemical changes is crucial for scientific literacy. The following tips offer practical guidance for identifying processes where materials are altered without changing their chemical composition.

Tip 1: Consider Reversibility: Physical changes are often easily reversed. Ground coffee, though changed in form, can be conceptually reconstituted into a single bean (though not practically). This contrasts with burning wood, where the original material cannot be retrieved from the ash and gases.

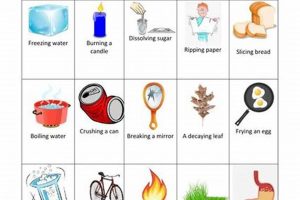

Tip 2: Look for Changes in Form: Crushing, grinding, cutting, and melting are all indicative of physical changes. The substance’s shape, size, or state of matter is altered, but its inherent chemical properties remain consistent.

Tip 3: No New Substances Formed: A key indicator of a physical change is the absence of new chemical substances. If the composition remains identical before and after the process, it’s likely a physical change.

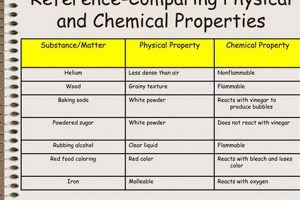

Tip 4: Observe Changes in Physical Properties: Physical changes often manifest as alterations in density, texture, color, or state (solid, liquid, gas). These changes do not reflect a change in the underlying chemical structure.

Tip 5: Contrast with Chemical Change Indicators: Indicators of chemical change include the release of gas, formation of a precipitate, change in temperature, or a change in color that signifies a new substance (like rust formation).

Tip 6: Consider Dissolution: Dissolving a substance, like sugar in water, is a physical change. The sugar molecules are dispersed within the water, but no new chemical bonds are formed. The sugar can be recovered by evaporating the water.

Recognizing these characteristics allows for accurate categorization of changes in matter, facilitating a deeper understanding of the properties and behaviors of substances in diverse contexts.

By applying these principles, a more comprehensive understanding of the nature of matter and its transformations can be achieved.

1. Physical Processes

Physical processes involve alterations in a substance’s form, state, or appearance without affecting its chemical composition. These processes are characterized by the absence of new substance formation. In the context of grinding, the material undergoes a physical change as its particle size decreases, but its chemical identity remains unchanged. This distinction is crucial for understanding material behavior and processing outcomes. Consider the example of rock erosion: physical forces break down the rock into smaller fragments, but the mineral composition remains the same.

The concept of a physical process is fundamental to classifying changes in matter. Grinding exemplifies a physical process because it alters the physical properties (particle size and surface area) of a substance without affecting its chemical makeup. Practical applications of this understanding are numerous, ranging from pharmaceutical development where grinding influences drug dissolution rates, to mineral processing where particle size affects extraction efficiency. Another example is food processing where grinding alters texture and influences flavor release.

Categorizing grinding as a physical process highlights the importance of differentiating between transformations that affect form and those that alter composition. This understanding has significant implications in diverse fields, including manufacturing, geology, and food science. Challenges remain in predicting the precise effects of grinding on specific materials, particularly in complex mixtures. Further research into the mechanics of grinding and its impact on material properties continues to advance technological applications and scientific understanding of physical processes.

2. No New Substance

A fundamental principle in classifying changes in matter involves determining whether new substances are formed. This criterion distinguishes physical changes, where the original substance retains its chemical identity, from chemical changes, where new substances with different properties emerge. The absence of new substance formation is a key indicator that a process, such as grinding, represents a physical change.

- Substance Identity Preservation

Grinding reduces particle size without altering the fundamental chemical composition. The substance before grinding and the resulting smaller particles are chemically identical. This preservation of chemical identity signifies a physical change. For instance, grinding quartz crystals results in smaller quartz particles, not a different material.

- Chemical Bonds Remain Unchanged

In a physical change like grinding, the chemical bonds within the substance remain intact. No new bonds are formed, and existing bonds are not broken. This contrasts with chemical changes where bonds are rearranged or broken, leading to new substances. Grinding coffee beans, for instance, doesn’t alter the chemical bonds within the coffee molecules.

- Reversibility (in Principle)

While often impractical, physical changes are theoretically reversible. The ground substance could, in principle, be reassembled into its original form without chemical alteration. This potential for reversal further underscores the absence of new substances formed during grinding. Though reassembling ground coffee into its original bean form is not feasible, the conceptual possibility highlights the nature of the physical change.

- Contrast with Chemical Changes

Chemical changes intrinsically involve the formation of new substances with distinct properties. Burning wood, for instance, produces ash and gases, substances chemically different from the original wood. This stark contrast highlights the significance of “no new substance” as a defining characteristic of physical changes like grinding.

The principle of “no new substance” is central to understanding the distinction between physical and chemical changes. Grinding, exemplified by its preservation of substance identity, unchanged chemical bonds, and theoretical reversibility, stands as a clear example of a physical change. This understanding is critical for predicting and controlling outcomes in various processes across disciplines like materials science, pharmaceuticals, and geology.

3. Altered Particle Size

Particle size reduction is a central aspect of grinding and plays a key role in determining whether the process results in a physical or chemical change. Examining how grinding alters particle size without affecting chemical composition clarifies its classification as a physical process. This exploration delves into the implications of altered particle size, emphasizing its relevance to various fields.

- Surface Area Increase

Grinding significantly increases the surface area of a substance. Smaller particles collectively possess a larger surface area than the original, larger piece. This increased surface area has substantial implications for chemical reactions, influencing reaction rates and material interactions. For example, finely ground flour reacts more readily with baking powder than coarser flour, impacting the final product. Despite this change in reactivity, the chemical composition of the flour remains the same, demonstrating the physical nature of the change.

- Physical Property Modification

Altered particle size directly influences physical properties such as texture, appearance, and flow characteristics. Grinding alters the texture of food, influencing mouthfeel and digestibility. In pharmaceuticals, particle size affects drug dissolution rates and bioavailability. These changes, while noticeable, do not alter the fundamental chemical composition of the substance. Grinding pigments, for instance, alters color intensity and texture but not the chemical identity of the pigment.

- Energy Input Requirement

Reducing particle size requires energy input. The force applied during grinding is converted into mechanical energy, breaking down the material into smaller pieces. This energy requirement underscores the physical nature of the process, as it involves work done on the substance without altering its chemical bonds. The energy needed to grind rocks, for example, is a measure of the physical work involved in changing their size.

- Reversibility in Principle

Despite practical limitations, the reduction in particle size through grinding remains, in principle, reversible. While technically challenging, the smaller particles could theoretically be reassembled into the original larger piece without chemical alteration. This conceptual reversibility reinforces the classification of grinding as a physical change. Although reconstituting ground coffee into the original beans is practically impossible, the theoretical possibility highlights the physical nature of the change.

The alteration of particle size through grinding stands as a defining characteristic of a physical change. The increase in surface area, modification of physical properties, energy requirements, and theoretical reversibility collectively demonstrate that grinding affects physical attributes without altering the fundamental chemical composition of the material. This understanding is paramount for manipulating and utilizing materials effectively across various fields.

4. Reversible, in principle

Reversibility, while often a theoretical concept rather than a practical reality, serves as a key criterion for distinguishing physical changes from chemical changes. In the context of determining whether grinding constitutes a physical or chemical change, the principle of reversibility offers valuable insight. Exploring the theoretical reversibility of grinding clarifies its classification as a physical process.

- Conceptual Reassembly

Grinding, fundamentally a process of reducing particle size, is theoretically reversible. While practically challenging, the resulting smaller particles could conceptually be reassembled into the original larger form without altering the chemical composition. This notion of reassembly, though not always feasible, highlights the physical nature of the change. Imagine grinding a diamond into dust; though practically impossible to reconstruct, the dust remains chemically identical to the original diamond, and theoretically, it could be reformed.

- Preservation of Chemical Bonds

The theoretical reversibility of grinding stems from the preservation of chemical bonds within the substance. Grinding does not break or form new chemical bonds; it merely alters the physical arrangement of the material. Because the chemical identity remains unchanged, the process is, in principle, reversible. Dissolving sugar in water is another example; while the sugar seems to disappear, its chemical identity is preserved, and it can be recovered by evaporating the water.

- Distinction from Chemical Changes

Chemical changes, by their nature, are not readily reversible. The formation of new substances with different chemical properties through bond breaking and formation prevents simple reversal to the original state. Burning wood, for example, results in ash and gaseschemically distinct from the original woodmaking the process irreversible. This contrast underscores the significance of reversibility in identifying physical changes like grinding.

- Practical Limitations

While grinding is theoretically reversible, practical limitations often prevent actual reassembly. The complexity of reconstructing the exact original form, especially with numerous small particles, poses significant challenges. However, these practical constraints do not negate the fundamental principle of reversibility in classifying the process as physical. Consider a shattered glass; while theoretically possible to fuse the pieces back together perfectly, the practical difficulty does not change the fact that the shattering was a physical change.

The principle of “reversible, in principle” provides a valuable framework for understanding the nature of grinding. While practical limitations may exist, the theoretical possibility of reversing the process, based on the preservation of chemical identity and bonds, firmly establishes grinding as a physical change. This concept plays a critical role in differentiating physical processes from chemical reactions, impacting fields ranging from materials science to geology.

5. Preserved Composition

Preserved composition is the defining characteristic distinguishing physical changes from chemical changes. In a physical change, the substance retains its original chemical makeup, even if its physical form alters. This principle directly addresses the question of whether grinding constitutes a physical or chemical change. Because grinding reduces particle size without altering the underlying chemical composition, it is classified as a physical change. The chemical bonds within the substance remain unchanged, and no new substances are formed. For instance, grinding sodium chloride (table salt) into a finer powder changes its texture and appearance but not its chemical identity; it remains sodium chloride.

This concept has significant practical implications. In pharmaceuticals, grinding medications to control particle size affects dissolution rate and bioavailability, but the therapeutic effect remains linked to the preserved chemical composition of the drug. Similarly, grinding ores in mineral processing increases surface area for chemical reactions during extraction, but the target metal’s chemical identity remains unaffected. Understanding preserved composition is crucial for controlling and predicting outcomes in various processes across multiple disciplines. For example, grinding coffee beans alters their form, impacting brewing and flavor, but the chemical compounds responsible for the coffee’s distinct taste and aroma are preserved, ensuring the final beverage remains coffee.

Preserved composition is therefore essential for differentiating physical processes like grinding from chemical reactions. This understanding underpins numerous industrial processes and scientific endeavors. Challenges remain in predicting the exact effects of particle size reduction on material properties, especially in complex mixtures, emphasizing the need for continued research. The principle of preserved composition remains a cornerstone of material science and related fields, enabling precise manipulation and utilization of substances while maintaining their inherent chemical identity.

Frequently Asked Questions

The following addresses common inquiries regarding the nature of grinding as a physical change.

Question 1: Does grinding alter the inherent properties of a substance?

Grinding alters physical properties like particle size, surface area, and texture but not the inherent chemical composition or identity of the substance. A ground diamond, while different in appearance, remains chemically a diamond.

Question 2: Why is grinding considered a physical change despite its impact on reactivity?

Increased surface area from grinding can enhance reactivity by providing more sites for interaction. However, this increased reactivity doesn’t change the underlying chemical composition; it simply facilitates existing potential reactions. Finely ground iron rusts faster than a solid block due to increased surface area exposed to oxygen, but the chemical process of rusting remains the same.

Question 3: Is it possible to reverse the effects of grinding?

Theoretically, grinding is reversible. The smaller particles could, in principle, be reassembled to recreate the original form. However, this is often practically impossible due to the complexity of reconstructing the precise original structure. Ground coffee, for example, cannot be perfectly reformed into the original beans.

Question 4: How does grinding differ from chemical processes like combustion?

Grinding alters form without changing chemical composition. Combustion involves chemical reactions that transform the original substance into new substances with different properties. Burning wood, for instance, produces ash and gases, chemically different from the original wood.

Question 5: Are there instances where grinding can induce chemical changes?

While grinding itself is a physical process, it can indirectly facilitate chemical changes. Increased surface area can accelerate reactions by providing more contact points. For example, grinding a flammable material into a fine powder increases its flammability by exposing more surface area to oxygen, but the act of grinding itself does not change the material’s chemical composition.

Question 6: Why is understanding the classification of grinding important?

Classifying grinding as a physical change is crucial for predicting and controlling outcomes in various fields. From pharmaceutical development to mineral processing and material science, this understanding allows for precise manipulation of materials to achieve desired properties without altering their chemical identity.

Understanding grinding as a physical process is essential for material science, industrial applications, and general scientific literacy. The distinction between physical and chemical changes clarifies how matter interacts and transforms, informing practical applications and theoretical understanding alike.

Further exploration will delve into specific applications of grinding across various disciplines.

Conclusion

Grinding, characterized by particle size reduction without alteration of chemical composition, stands as a definitive example of a physical change. This conclusion rests upon consistent observations: no new substances form, chemical bonds remain unaltered, and the process is theoretically reversible. While grinding modifies physical attributes such as surface area, texture, and reactivity, the inherent chemical identity of the substance persists. This distinction carries substantial implications across diverse fields, from pharmaceuticals and material science to geology and food processing, where controlled particle size influences material properties and process outcomes.

Further investigation into the nuanced effects of grinding on specific materials and in complex systems remains crucial for advancing technological applications and scientific understanding. A thorough comprehension of the distinction between physical and chemical changes, exemplified by the analysis of grinding, empowers informed decision-making in material manipulation and process optimization across various disciplines. This knowledge base provides a foundation for continued innovation and exploration in material science and beyond.